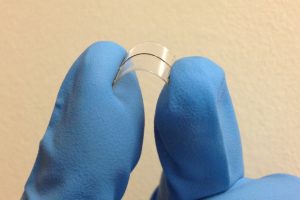

A recent study at Sharif University of Technology has led to the design and fabrication of a flexible supercapacitor that can be used in industrial systems, wearable devices, and clean energy platforms such as wind turbines and solar cells. In this project, novel electrodes based on nickel–cobalt sulfide conductive textiles, polyaniline, and manganese oxide, integrated with nitrogen- and sulfur-doped carbon nanofibers, were developed to significantly enhance the energy storage capacity and cyclic durability of the device.

According to the Report, This project was conducted as part of the postdoctoral research of Dr. Zahra Karami under the supervision of Dr. Saeed Shahrokhian Dehkordi, marking a major step toward developing lightweight, flexible, and sustainable energy storage systems—key components for the future of wearable electronics and advanced energy technologies.

In the course of this research at Sharif University of Technology, a team of scientists succeeded in fabricating flexible hybrid supercapacitors composed of conductive fabrics combined with advanced nanomaterials. With high performance and low weight, these supercapacitors can serve as energy storage units for wearable electronics, medical devices, industrial equipment, and even wind and solar power systems.

Dr. Zahra Karami, a postdoctoral researcher in Textile Chemical Engineering from Isfahan University of Technology and the principal investigator of the project, explained that the growing use of wearable and portable devices in fields such as medicine, sports, defense, and electronics has made the demand for lightweight and flexible energy storage systems more evident than ever. According to her, conventional energy storage systems, due to their heavy weight, large volume, and lack of flexibility, are unsuitable for such applications, motivating the researchers to explore new substrate designs.

Karami added: “In this research, conductive textiles were used as the main substrate because these materials, in addition to being lightweight and mechanically flexible, possess a porous structure and high surface area, which allow them to be coated with electroactive materials. Among various textiles, carbon fiber felts, owing to their high electrical conductivity and mechanical stability, were identified as ideal candidates for electrode fabrication.”

She further explained that the developed supercapacitors are of the solid-state type and, compared to conventional ones, offer advantages such as higher power density, faster charge–discharge rate, enhanced safety, and physical flexibility. These features make them suitable for wearable electronic devices, including health monitors, biosensors, electronic skins, and wearable mobile gadgets.

According to Karami, the main objective of the project was to improve the capacitive performance of carbon felt electrodes. Through the induction of pseudocapacitive properties and the use of simple, rapid, and cost-effective synthesis methods, the team produced electrodes with high capacitance and notable electrochemical stability. These electrodes were employed to construct flexible all-solid-state supercapacitors that outperformed conventional types in terms of energy density, potential window, and cycling stability.

The researchers emphasized that the developed technology could pave the way for the industrial-scale production of portable energy storage systems. The new supercapacitors are not only suitable for wearable electronics but can also be integrated into larger-scale clean energy systems, such as wind turbines, solar panels, and renewable energy storage units. The advancement of such technologies represents a significant step toward the transition to green energy and the emergence of intelligent wearable systems.